Description

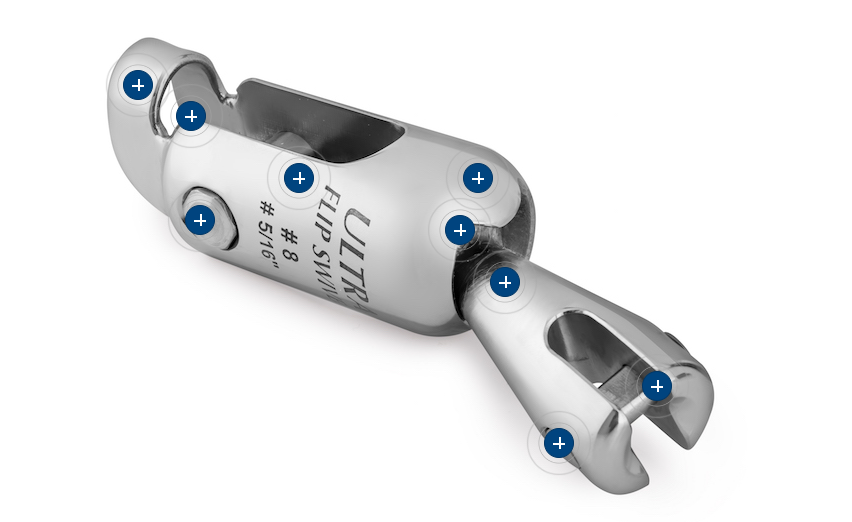

The Ultra Marine Flip Swivel is a superb piece of marine design and engineering, culminating in a one-piece anchor connector solution that requires no additional shackles.

Included in the Box:

Flip Swivel, Hook Brake, appropriate size Allen keys

Ultra Flip Swivel Specification:

- Manufactured from 316 stainless steel by Ultra Marine Anchors in the Czech Republic

- Manufacturer 3-year warranty

- Individually stamped on the body with the manufacturer break load

- Designed so that the breaking strain exceeds that of a typical anchor chain of the same size

- Allows 360-degree swivelling and also 30 degrees of articulation

- One-piece body with a flipping nub ensures the anchor is always retrieved in the correct plane.

- Hexagonal head locking bolt – does not require any further security measures

Ultra Flip Swivel Facts, Features and Plus Factors:

One Piece Solution: The CNC (computer numeric control) machined one-piece body and head (with integral spherical ball) ensures maximum strength

Universal – suitable for most anchor designs, not just the Ultra anchor

Semi-Spherical Ball: Self-cleaning and allows 360-degree rotation

Hexagonal Head Bolts: Ensures the locking bolt is 100% secure and cannot release itself accidentally – Allen keys for other end supplied

TEFLON* O-Ring: the internal ring stops metal friction occurring when under load, providing low resistance and smooth operation

Flipping Nub: If the anchor is recovered upside down, the flip nub will assist the anchor to right itself onto the roller correctly

Rounded Corners: prevent potential damage to the deck or injury to the crew

Throat Opening: The aperture is specifically designed to fit the chain size

Specifications: The swivel chain size and the breaking strength are recorded on the rear side of the swivel

Warranty: All ULTRA Swivels are supplied with a standard five-year warranty

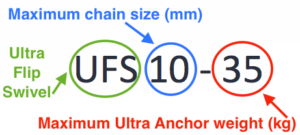

ULTRA Flip Swivel Code Explanation :

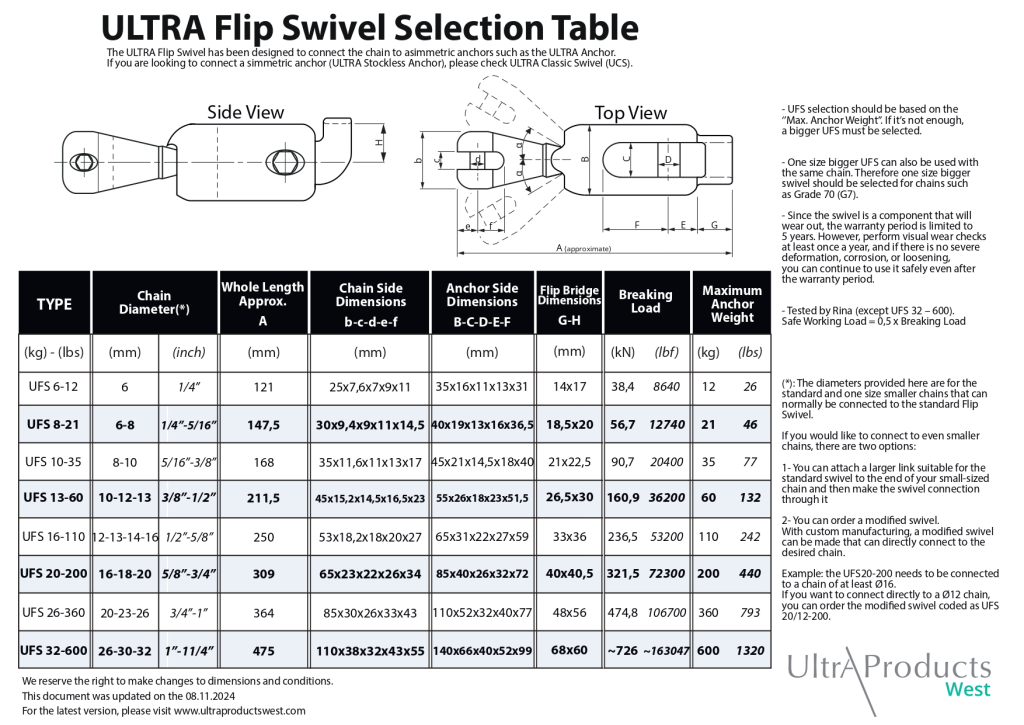

Selection Table

Product Maintenance

ULTRA Swivel – Safety and Usage Instructions

- The ULTRA Swivel is designed to be used safely for many years. However, due to its critical role in safety, some routine inspections are recommended.

- At least once a year, a visual inspection should be conducted to check for any unexpected issues.

- If the spherical joint is mineral-coated, applying a water-resistant lithium-based grease will help it operate smoothly.

- The pin set screws are designed not to loosen on their own. It must be ensured that this condition has not changed for any reason.

- A small amount of indentation on the neck caused by the jaw of the joint is normal. This indentation occurs when the anchor self-corrects after being retrieved in the wrong orientation. It is a sign of how often the self-correcting mechanism has been active and is only an aesthetic issue. Over time, this indentation is expected to slow down and not continue excessively. However, if the diameter at the indented area becomes smaller than the diameter where the neck meets the sphere, the swivel’s safety is compromised. The cause of such excessive stress should be identified and resolved, and the swivel must be replaced with a new one. Otherwise, continued use may result in failure of the swivel.

Possible Causes of This Situation:

- Using the swivel with a heavier anchor than specified in the selection table, i.e., using a smaller swivel than recommended.

- Connecting a high-strength chain to a small swivel. In this case, the small swivel will be subjected to excessive forces and wear. A swivel with a breaking strength greater than that of the chain should be selected.

- A bow roller that is too narrow to allow the anchor to move sideways during self-correction.

- A special groove on the bow roller for chain links, which hinders the rotation of the anchor and creates more problems than benefits.

- Using a high-speed windlass. It does not allow sufficient time for the anchor to self-correct, leading to excessive stress on the swivel. To prevent this, stop the windlass for about 1 second when the swivel reaches the roller. Resume retrieval after the anchor rotates and corrects itself to avoid excessive strain.

IMPORTANT NOTES:

- The above recommendations must be followed. Ignoring them may lead to situations that pose risks to life and property. In such cases, the manufacturer and sellers of the ULTRA Swivel bear no responsibility whatsoever.

- If the above recommendations are not followed, the warranty of the ULTRA Swivel becomes void.

Anchor Locking Hook

When the anchor is retrieved and seated on the bow roller, an anchor locking hook should be used to prevent it from unintentionally deploying back into the sea.

This hook should be attached to the gap at the end of the anchor arm where it connects to the swivel body.

It must then be tightened and secured (volta) to the nearest cleat.

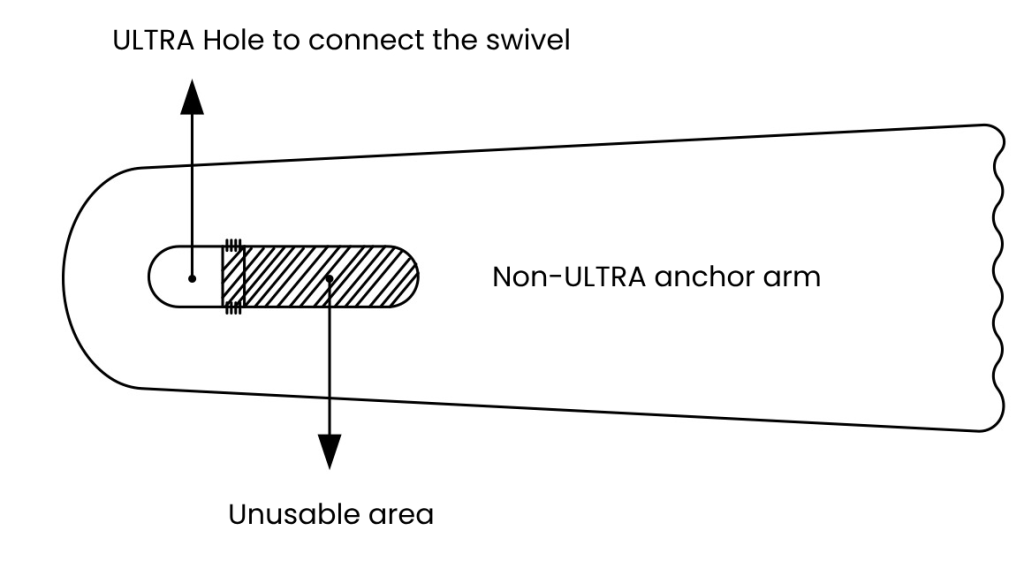

Oval Hole Anchor Connection

Most of the anchors made with the old understanding have an oval connection hole at the end of the arm. The reason for this is to be able to use U (or D) locks when connecting anchors from the times when swivels were not sufficiently developed. All technical features and safety of the ULTRA Swivel are far ahead of U (or D) locks in the same group. However, if you connect the ULTRA Swivel to a non-ULTRA anchor with an oval hole at the end of the handle, it may sometimes, although very rarely, contract and lock in an undesirable position during movement. If you want to completely eliminate this rare possibility, it would be appropriate to prevent the unnecessary backward clearance of the oval hole with a small modification.